|

|

| The ERA Story

The history of ERA and the story behind the development of the ERA Mini Turbo. |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

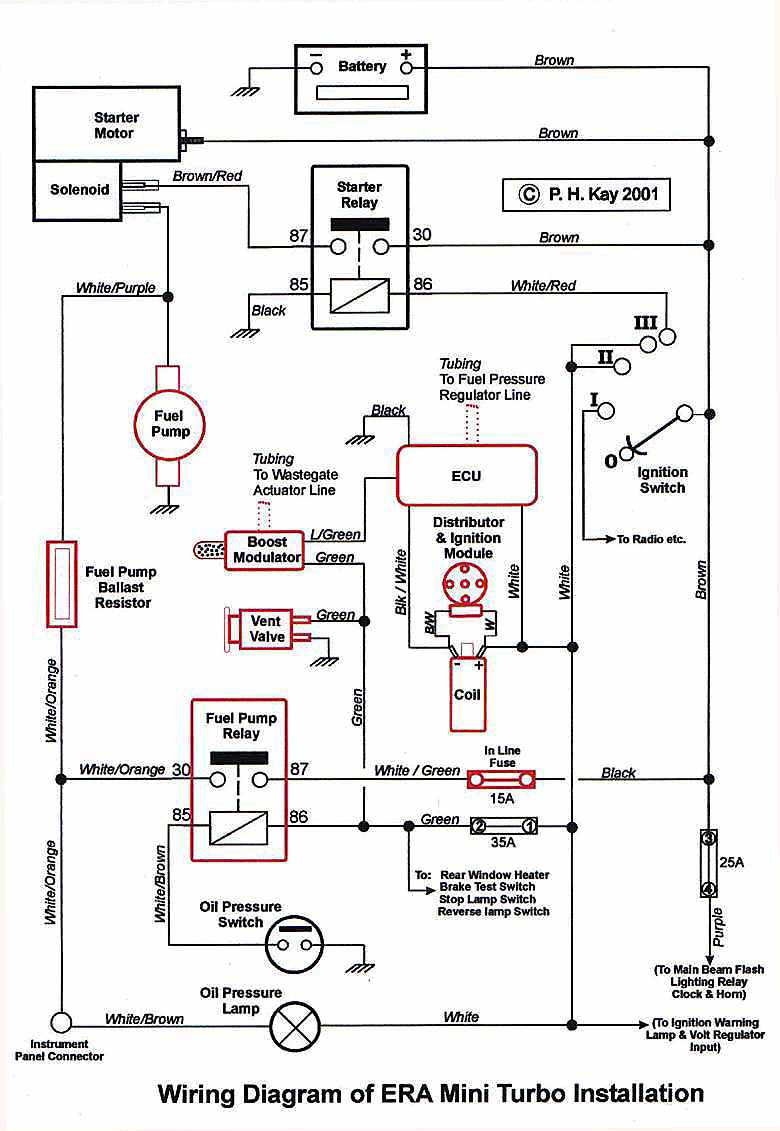

Mini Turbo Installation - Wiring Diagram and Circuit Description

Please Note: On the following diagram, all items that are unique to the turbo installation are outlined in red.

Circuit Description

When the ignition key is set to position II, normal ‘Ignition On’,

Battery positive is supplied, via the white wire, to the ignition Coil, ECU,

and to one side of fuse 1–2 in the fuse box (the top fuse). The engine

has, therefore, all requirements for starting. In addition, with power at

fuse 1–2, the coil of the Fuel Pump Relay has battery volts at its

coil terminal 86. The other side of the coil, at terminal 85, is however

not connected to chassis until the oil pressure switch closes, which only

occurs when the engine starts and sufficient oil pressure has been generated.

The Oil Pressure Lamp has battery positive at one side, via the white wire.

Its other side is connected to near chassis via the Fuel Pump and its associated

Ballast Resistor. The lamp will therefore illuminate, indicating low oil

pressure. (Note: Since the current taken by the bulb is very small, the combined

voltage drop across the Ballast Resistor and stationery Fuel Pump windings

will be extremely small.)

When the Ignition Switch is set to position III, the ‘Start’ position,

battery positive is now also applied to the coil of the Starter Relay at

terminal 86, via the white/red wire. Since the other side of the coil at

85 is connected to chassis, the relay energises. Battery positive is therefore

switched to the Solenoid, via contacts 30 and 87 which then supplies the

Starter Motor. Whilst the Starter is energised, a separate auxiliary contact

on the Solenoid, feeds power to the Fuel Pump. The pump now runs, filling

the carburettor bowl with fuel.

Whilst the Ignition Switch is at position III, connection is still made to

the contact at position II, the normal ‘Ignition On’ position,

thus maintaining the initial ‘Ignition ON’ conditions previously

described. The Oil Pressure Lamp will, however, extinguish whilst the Solenoid

is energised, as battery positive is applied to both sides of the lamp in

this condition.

After the engine starts, the ignition key is released and returns under spring

tension to position II. The ignition supply remains connected, but the supply

to the Solenoid and therefore the Fuel Pump is removed. The engine continues

to run however, using the fuel in the carburettor bowl, which will last for

approximately 30 seconds. Meanwhile, as soon as oil pressure reaches approximately

5psi, the Oil Pressure Switch closes, thus energising the Fuel Pump Relay.

Its contacts, between 87 and 30 therefore close, switching a permanent battery

supply, via the In Line fuse and the Fuel Pump Ballast Resistor, to the Fuel

Pump, which runs at a reduced voltage to prevent overheating. The voltage

at terminal 30 of the Fuel Pump Relay is also routed, via the white/orange

wire, to the Oil Pressure Lamp. This lamp is now supplied with battery positive

at both sides, causing it to extinguish.

In the event of the engine stopping for any reason, whilst the Ignition Switch is still at position II, e.g. in a crash, then the Oil Pressure Switch will open, causing the Fuel Pump Relay to de-energise, which will therefore remove the battery supply from the Fuel Pump and return the near chassis connection to the Oil Pressure lamp, the latter then illuminating.